home > Blogs

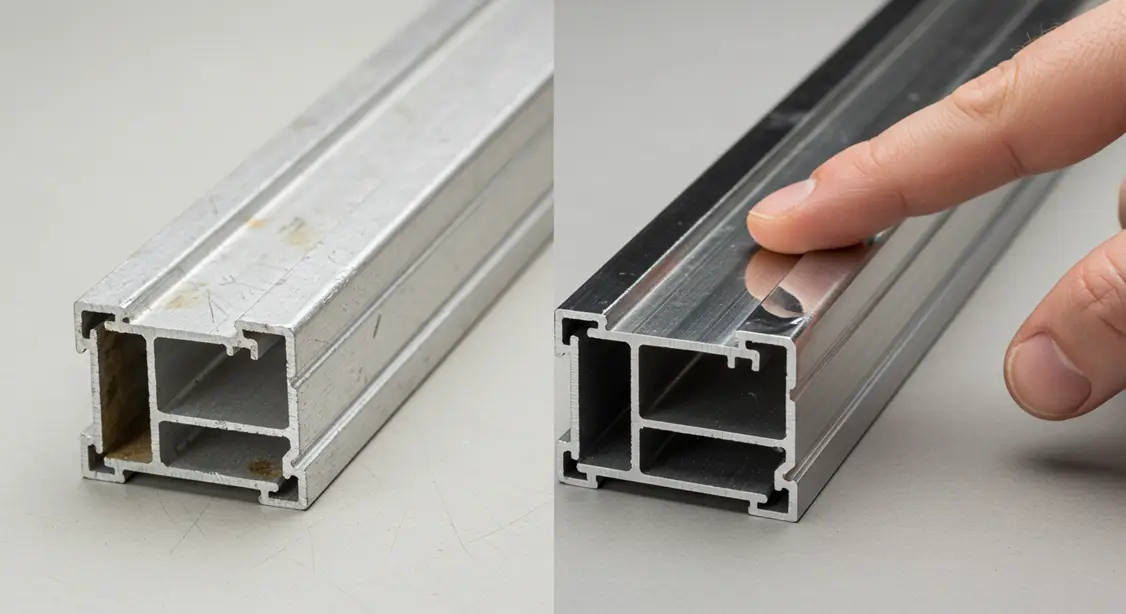

Anodizing is a powerful surface treatment that enhances the performance and aesthetics of aluminum. But what is the real difference between anodized and non-anodized aluminum? Let’s dive into the technical and practical distinctions.

Anodized aluminum undergoes an electrochemical process that forms a strong oxide layer bonded to the surface.

Advantages:

- Excellent corrosion and wear resistance

- Customizable stable colors

- Stronger and smoother surface

- Longer lifespan in harsh environments

This is raw aluminum with no additional surface treatment. It is more vulnerable to corrosion and has a dull appearance.

Disadvantages:

- Susceptible to oxidation

- Dull surface without color options

- Requires more maintenance

- Not suitable for outdoor use

We provide premium anodizing solutions using cutting-edge chemical and electrical processes. Clients can customize finishes based on color and gloss preferences, with guaranteed durability and professional quality.

If durability, beauty, and quality matter to you, anodized aluminum is the superior choice. It delivers lasting performance and elevates your product's value across all applications.